- Overview

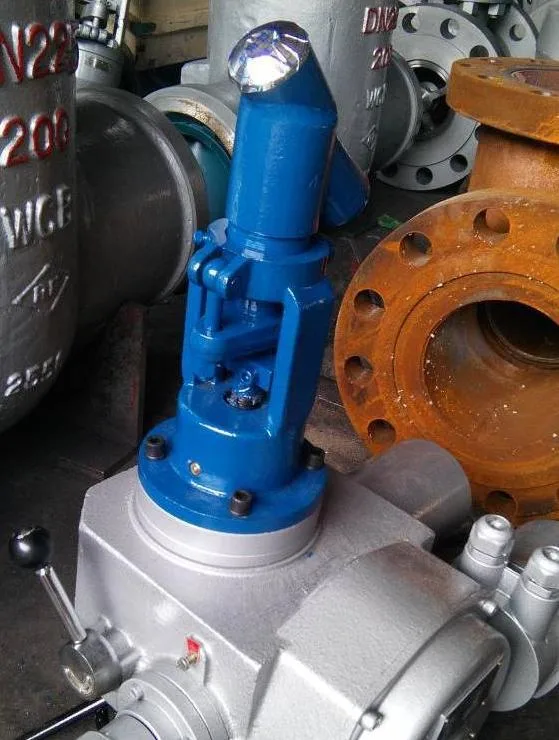

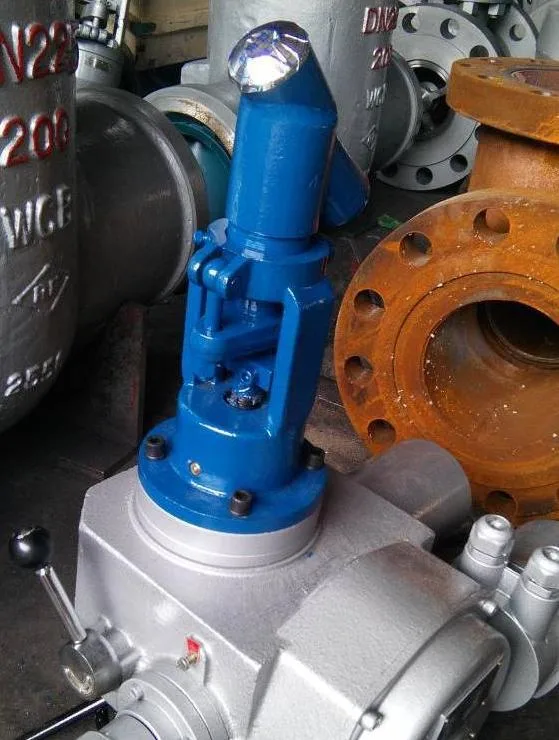

- Product Description

- Product Features

- Product Details

- View of the factory

Basic Info.

Model NO.

GAJ965Y

Size

2"-14"

Pressure

High Pressure

Transport Package

Plywood Case

Specification

ISO 9001

Trademark

GOOLE, OEM

Origin

China(Mainland)

HS Code

8481804090

Production Capacity

5000PCS/Year

Product Description

ANSI Pressure Seal Motorized Y Type Globe Valve (GAJ965Y)

The middle part of pressure seal globe valve using pressure self-tightening structure,make sure the valve has good sealing performance under high pressure and high temperature conditions,usually,the sealing ring has two kinds of material,one is low carbon steel,the other is flexible graphite+SS 316,besides,the sealing surface is welding with hard alloy,after the welding is finished,the thickness of metal layer should be 3mm or more,therefore,it has advantages of wear-resistant,temperature-resistant and anti-corrosion,greatly prolong the service life.Both ends adopt welding structure,the dimensions of welding groove can be customized on clients' requirements.The medium can be high temperature and high pressure water,steam,oil products and super-heated steam.,etc,it's widely used for thermal power plant,petrochemical industry,metallurgy and other industrial sectors.

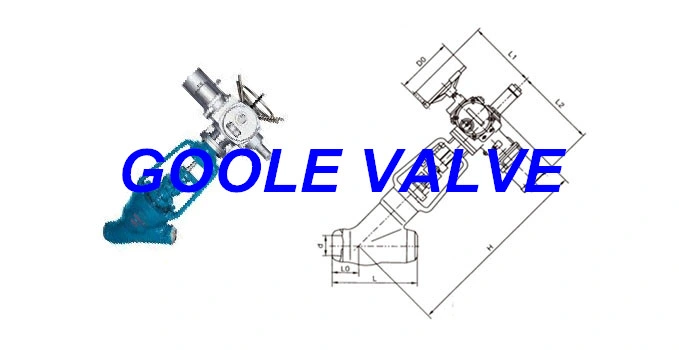

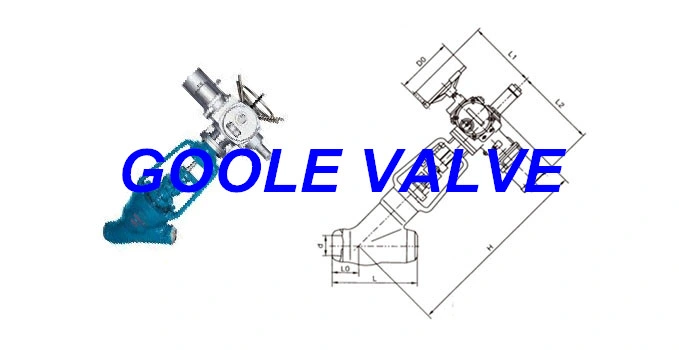

Main External Dimensions.

The middle part of pressure seal globe valve using pressure self-tightening structure,make sure the valve has good sealing performance under high pressure and high temperature conditions,usually,the sealing ring has two kinds of material,one is low carbon steel,the other is flexible graphite+SS 316,besides,the sealing surface is welding with hard alloy,after the welding is finished,the thickness of metal layer should be 3mm or more,therefore,it has advantages of wear-resistant,temperature-resistant and anti-corrosion,greatly prolong the service life.Both ends adopt welding structure,the dimensions of welding groove can be customized on clients' requirements.The medium can be high temperature and high pressure water,steam,oil products and super-heated steam.,etc,it's widely used for thermal power plant,petrochemical industry,metallurgy and other industrial sectors.

Main Features.

- The central connection adopt pressure self-tightening structure.

- The disc and seat are welding with hard alloy.

- High temperature creep resistance design.

- The material of stem is precipitation hardening stainless steel by nitriding.

- Operating device can be manual,gear,bevel gear and electric actuator.

Main Parts and Materials.

| Part Name | Material Mark | |||

| Body | WCB | WC1 | WC6 | WC9 |

| Disc | WCB | WC1 | WC6 | WC9 |

| Seat | 25 | 15CrMoA | 12Cr1MoVA | 12Cr1MoVA |

| Stem | 1Cr17Ni2 | 1Cr17Ni2 | SUH600 | SUH600 |

| 20Cr1Mo1V1A | 20Cr1Mo1V1A | |||

| Cover | 25 | 15CrMoA | 12Cr1MoVA | 12Cr1MoVA |

| WCB | WC1 | WC6 | WC9 | |

| Packing | Reinforced flexible graphite | |||

| Yoke | WCB | WCB | WCB | WCB |

| WC1 | WC6 | WC9 | ||

| Sealing ring | Mild steel(reinforced flexible graphite) | Mild steel | Mild steel | |

| Stem Nut | 45 | |||

| Suitable temp. | ≤425 °C | ≤450 °C | ≤540 °C | ≤570 °C |

Main External Dimensions.

| PN | DN | d | L | Lo | H | Do | L1 | L2 |

| 1500 LB | 3" | 64 | 368 | 140 | 990 | 305 | 410 | 565 |

| 4" | 84 | 457 | 170 | 990 | 305 | 420 | 654 | |

| 5" | 100 | 533 | 195 | 1115 | 305 | 420 | 654 | |

| 6" | 126 | 610 | 190 | 1763 | 457 | 440 | 688 | |

| 8" | 158 | 762 | 262 | 2026 | 457 | 440 | 688 | |

| PN | DN | d | L | Lo | H | Do | L1 | L2 |

| 2500LB | 2" | 38 | 310 | 120 | 810 | 305 | 400 | 555 |

| 2 1/2" | 46 | 340 | 130 | 895 | 305 | 400 | 555 | |

| 3" | 54 | 390 | 140 | 995 | 305 | 410 | 565 | |

| 4" | 70 | 480 | 170 | 1050 | 305 | 420 | 654 | |

| 5" | 86 | 580 | 195 | 1115 | 305 | 420 | 654 | |

| 6" | 104 | 630 | 200 | 1280 | 457 | 440 | 688 | |

| 8" | 130 | 770 | 260 | 1615 | 457 | 440 | 688 | |

| 10" | 162 | 930 | 300 | 1930 | 610 | 690 | ||

| 12" | 210 | 1060 | 360 | 2240 | 610 | 715 | ||

| 14" | 234 | 1160 | 395 | 2420 | 610 | 715 |