Basic Info.

Model NO.

AT52 AT63 AT75 AT83 AT92 AT105 AT125 AT140

Customized

Customized

Nominal Pressure

0.25-0.8MPa

Color

Color: Customizable

Transport Package

Foam+Carton Box+Wooden Case

Origin

China

Production Capacity

50000 Per Month

Packaging & Delivery

Package Size

35.00cm * 30.00cm * 30.00cm

Package Gross Weight

15.000kg

Product Description

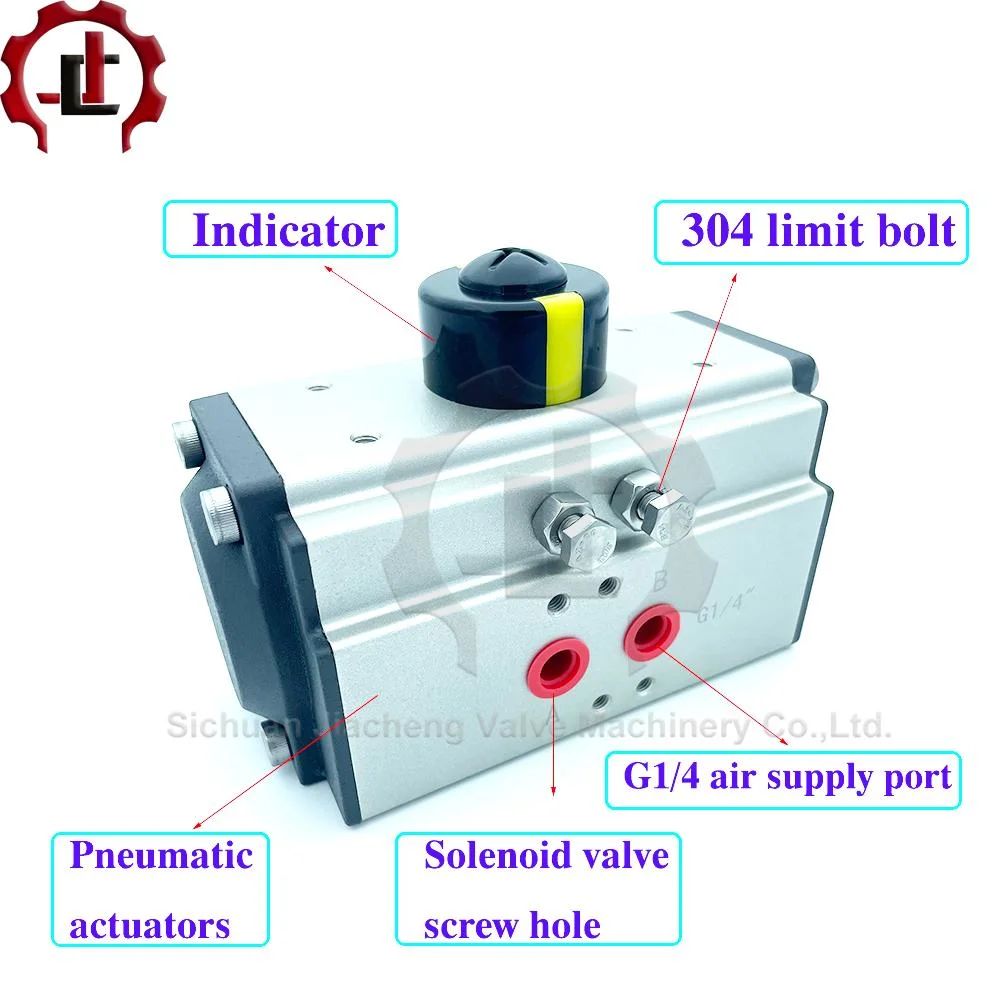

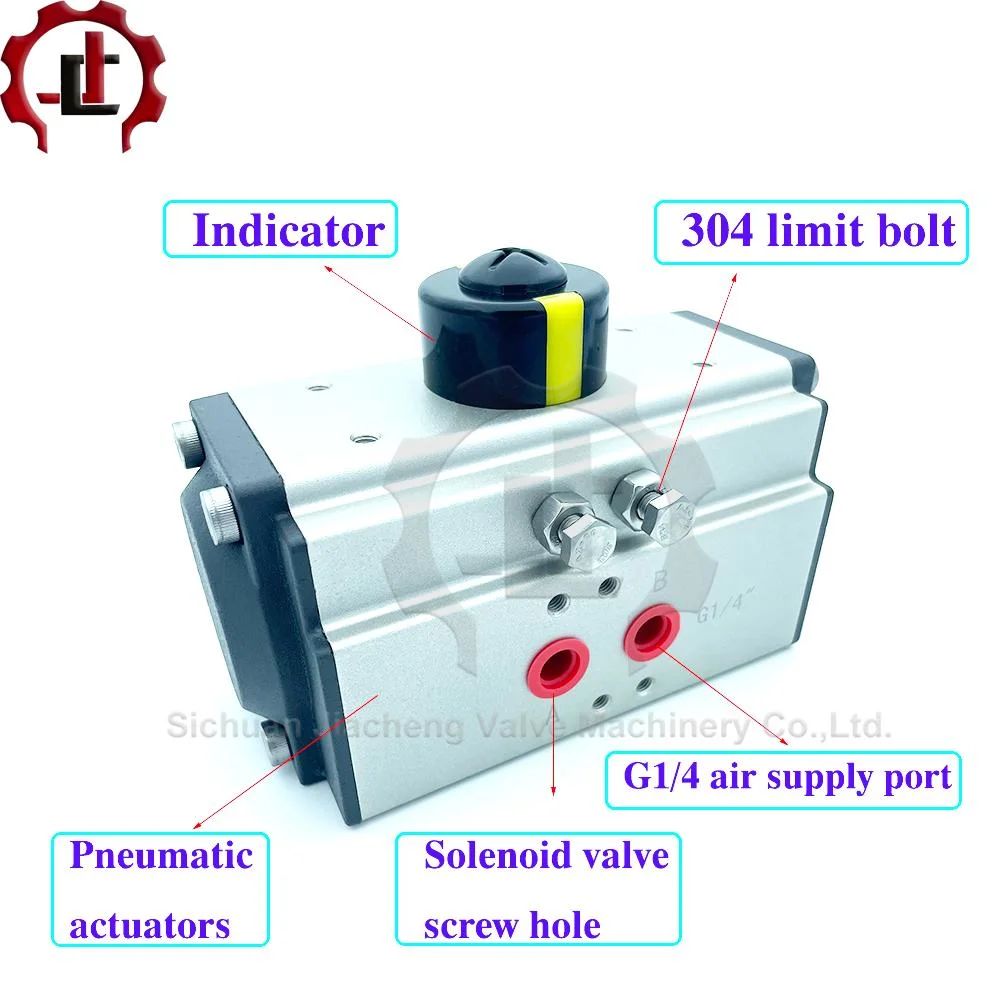

Product Model: AT-Pneumatic Actuator

Nominal pressure: 0.25-0.8Mpa

Material: aluminum alloy

Applicable scope: Ball valves, butterfly valves, three-way ball valves and other valves

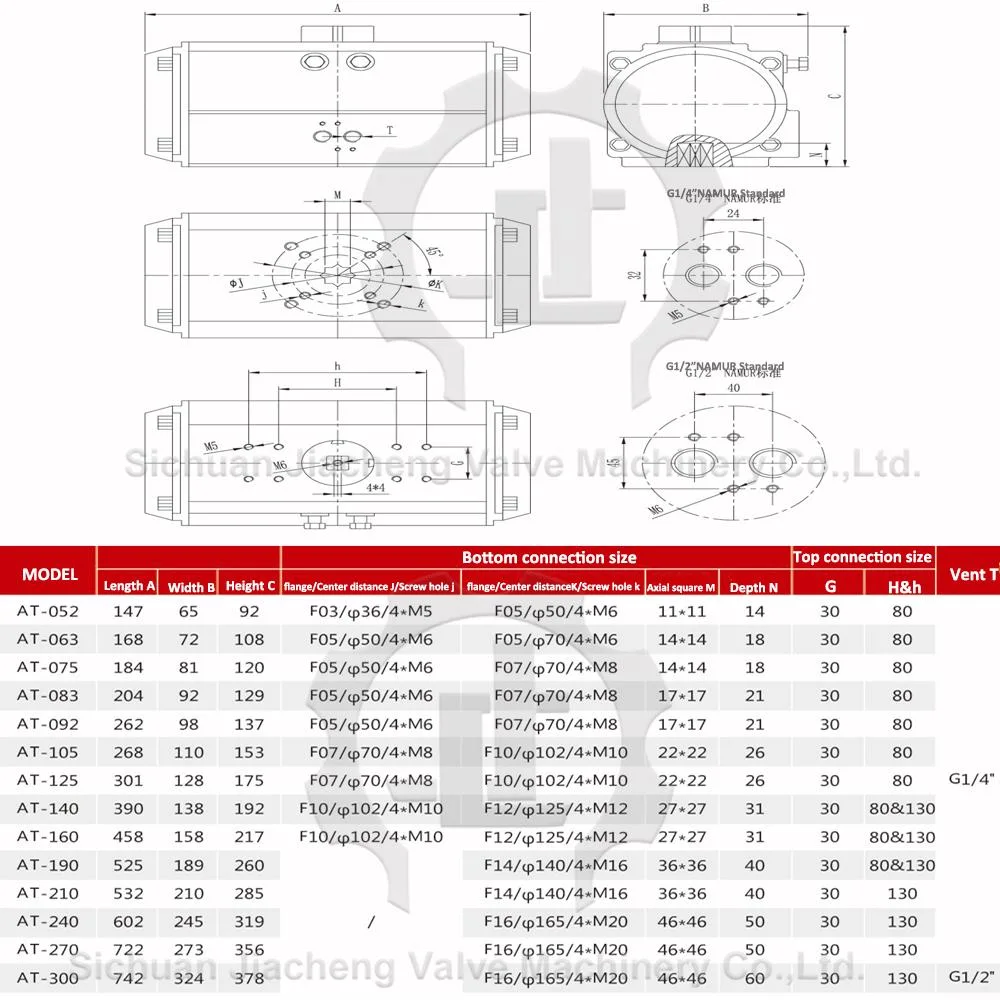

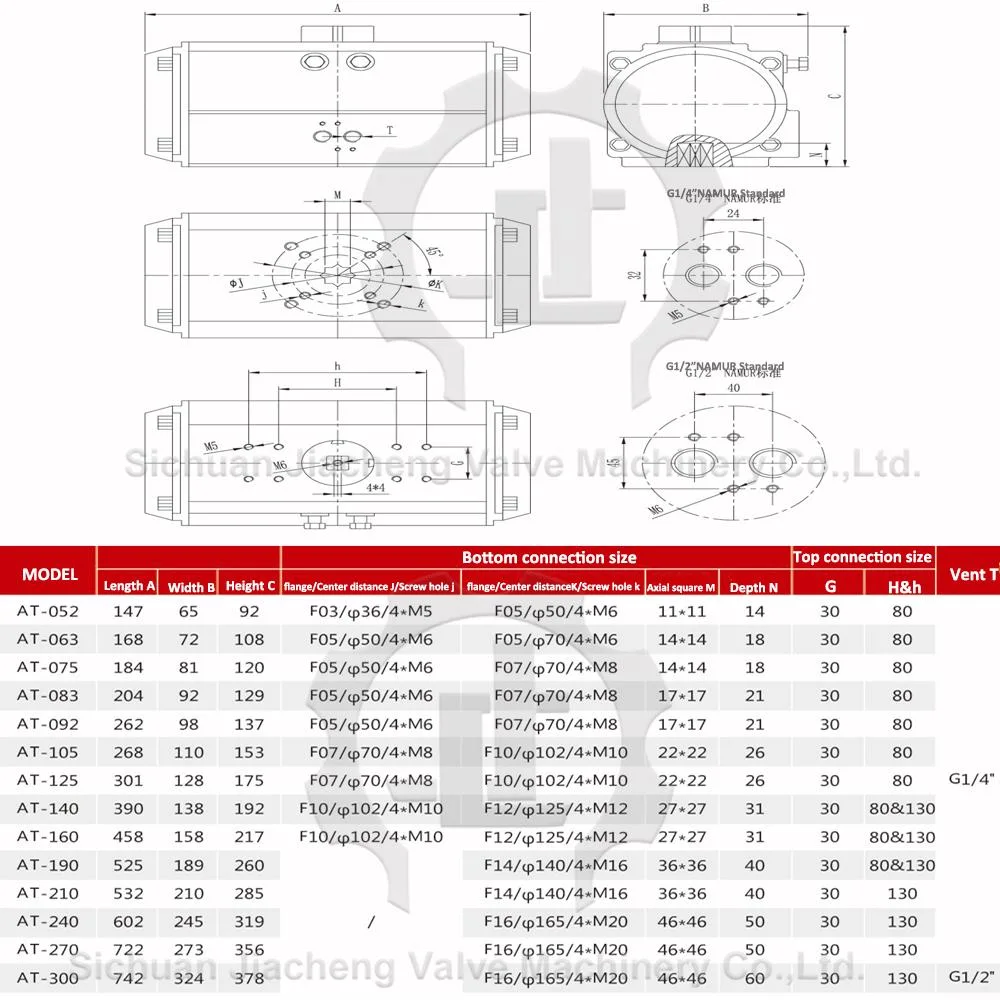

Main model: AT-52 AT-63 AT-75 AT-83 AT-92 AT-105 AT-125 AT-140 AT-160 AT-190 AT-210 AT-240

Gas cylinder: (aluminum alloy, the surface is oxidized by anodized hardening)

The application range of aluminum alloy after hard anodizing is very wide, involving textiles, bicycles, cameras, pneumatic components,

surgical instruments, optical instruments and other industries. It is suitable for cylinder liners, pistons, gears, impellers, guides, bearings, mold engineering member.

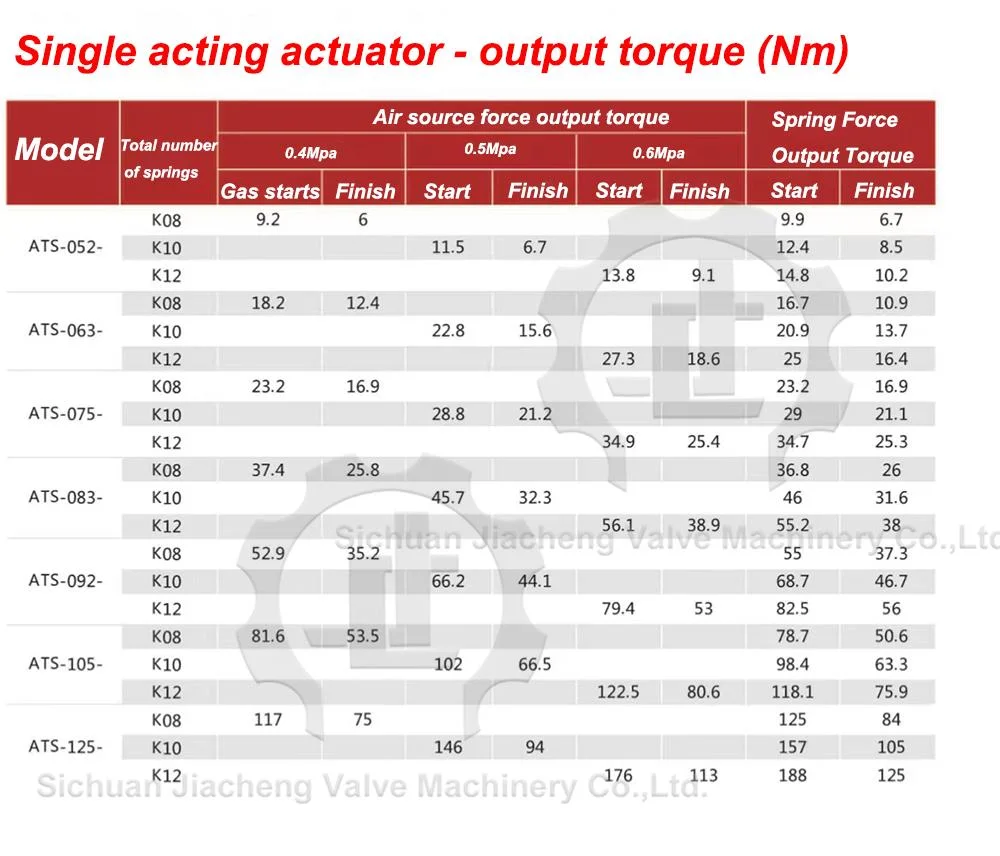

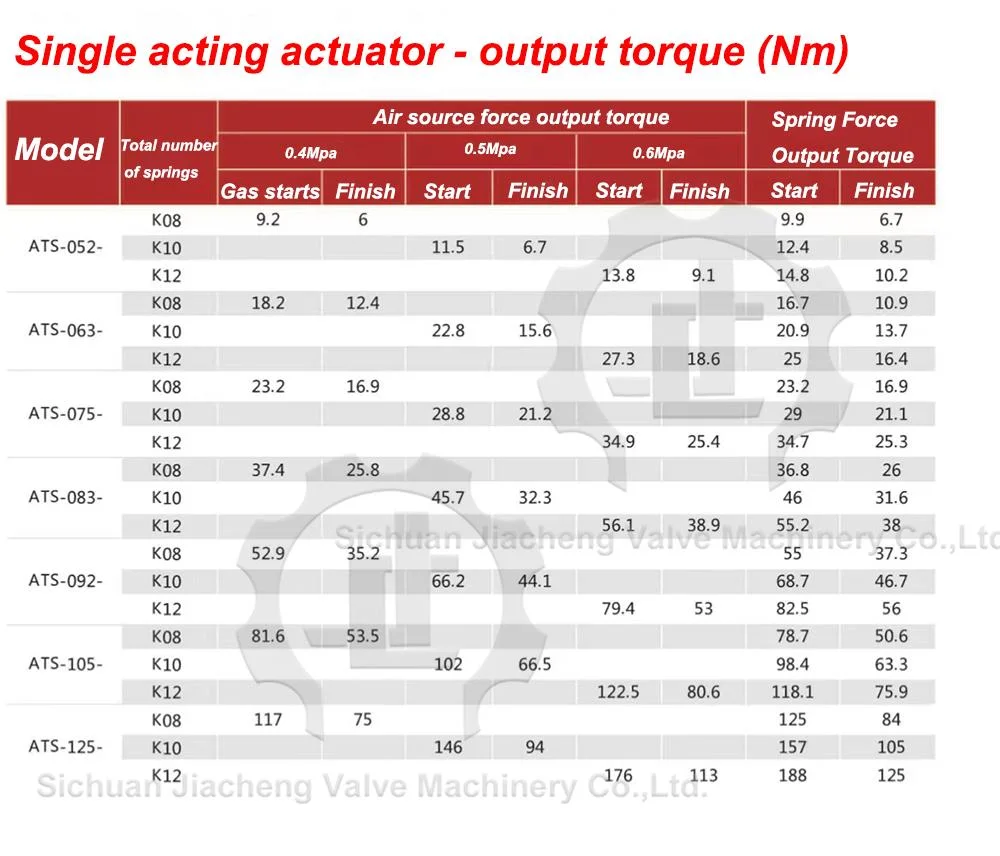

Selection of actuators:

When using our company's pneumatic actuator, first determine the torque required for the valve, considering the pipeline medium: dry clean, non-friction lubricating medium increases the safety value by 20%; water vapor or non-lubricating medium increases the safety value by 30%; non-lubricated dry Gas medium increases the safety value by 60%; non-lubricating gas conveying granular powder and other similar media increase the safety value by 90%. Then according to the pressure of the normal use of the air source, look up the corresponding torque table to get the accurate actuator model.

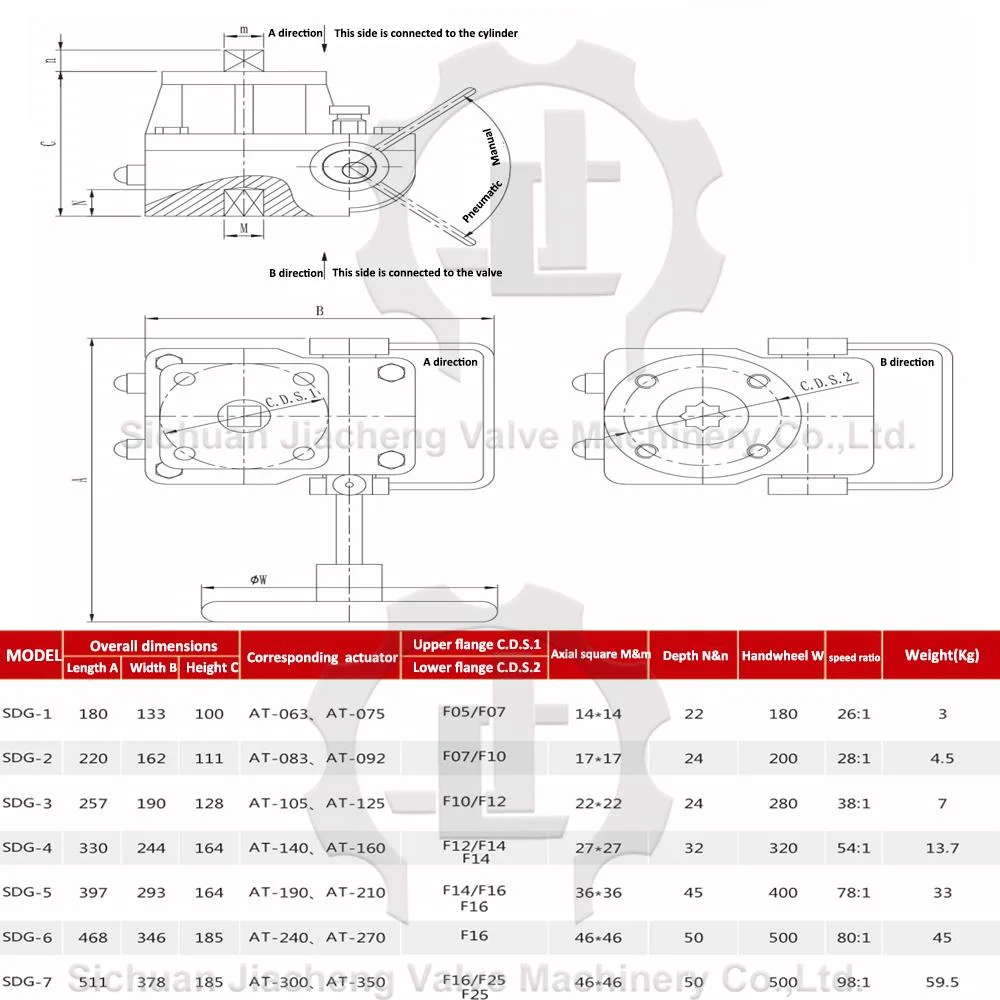

Actuator installation:

Whether the actuator and valve are installed correctly will directly affect the performance and life of the valve. Before the actuator is assembled with the valve, the torque of the valve should be measured, and the required torque should not be exceeded too much. After assembly, the pneumatic actuator and the valve are tested at the same time. The valve is pressurized to the rated sealing test pressure, and the valve is repeatedly opened and closed with the specified air source pressure. The switch is flexible and natural until there is no delay, jam or crawling, etc. Abnormal phenomenon, that is, the installation is qualified.

Tips: There are various models of this pneumatic actuator, and the weight varies greatly. Please contact us before placing an order.

Nominal pressure: 0.25-0.8Mpa

Material: aluminum alloy

Applicable scope: Ball valves, butterfly valves, three-way ball valves and other valves

Main model: AT-52 AT-63 AT-75 AT-83 AT-92 AT-105 AT-125 AT-140 AT-160 AT-190 AT-210 AT-240

Gas cylinder: (aluminum alloy, the surface is oxidized by anodized hardening)

The application range of aluminum alloy after hard anodizing is very wide, involving textiles, bicycles, cameras, pneumatic components,

surgical instruments, optical instruments and other industries. It is suitable for cylinder liners, pistons, gears, impellers, guides, bearings, mold engineering member.

Selection of actuators:

When using our company's pneumatic actuator, first determine the torque required for the valve, considering the pipeline medium: dry clean, non-friction lubricating medium increases the safety value by 20%; water vapor or non-lubricating medium increases the safety value by 30%; non-lubricated dry Gas medium increases the safety value by 60%; non-lubricating gas conveying granular powder and other similar media increase the safety value by 90%. Then according to the pressure of the normal use of the air source, look up the corresponding torque table to get the accurate actuator model.

Actuator installation:

Whether the actuator and valve are installed correctly will directly affect the performance and life of the valve. Before the actuator is assembled with the valve, the torque of the valve should be measured, and the required torque should not be exceeded too much. After assembly, the pneumatic actuator and the valve are tested at the same time. The valve is pressurized to the rated sealing test pressure, and the valve is repeatedly opened and closed with the specified air source pressure. The switch is flexible and natural until there is no delay, jam or crawling, etc. Abnormal phenomenon, that is, the installation is qualified.

Tips: There are various models of this pneumatic actuator, and the weight varies greatly. Please contact us before placing an order.