Basic Info.

Model NO.

G41F

Function

Solenoid Valve, Electronic Type, Intelligent Type

Usage

Flow Control

Standard

DIN, GB, ANSI, BSW, JIS

Size

Dn15-200

Body

CPVC

Stem

F6

Seat

PTFE

Air Supply

0.5MPa

Transport Package

Wooden

Specification

DN15-DN250

Trademark

yuefeng

Origin

Zhejiang Lishui

HS Code

8481804090

Production Capacity

5000

Product Description

MAIN FEATURES

Diaphragm valves (or membrane valves) consists of a valve body with two or more ports, a diaphragm, and a "weir or saddle" or seat upon which the diaphragm closes the valve. The valve is constructed from either plastic or metal.

Originally, the diaphragm valve was developed for use in industrial applications. Later on the design was adapted for use in the bio-pharmaceutical industry by using compliant materials that can withstand sanitizing and sterilizing methods.

There are two main categories of diaphragm valves: one type seals over a "weir" (saddle) and the other (sometimes called a "full bore or straight-way" valve) seals over a seat. The weir or saddle type is the most common in process applications and the seat-type is more commonly used in slurry applications to reduce blocking issues but exists also as a process valve. While diaphragm valves usually come in two-port forms (2/2-way diaphragm valve), they can also come with three ports (3/2-way diaphragm valves also called T-valves) and more (so called block-valves). When more than three ports are included, they generally require more than one diaphragm seat; however, special dual actuators can handle more ports with one membrane.

Diaphragm valves can be manual or automated. Their application is generally as shut-off valves in process systems within the industrial, food and beverage,pharmaceutical and biotech industries. The older generation of these valves is not suited for regulating and controlling process flows, however newer developments in this area have successfully tackled this problem.

In addition to the well known, two way shut off diaphragm valve, other types include: Three way zero deadleg valve, sterile access port, block and bleed, valbow and tank bottom valve.

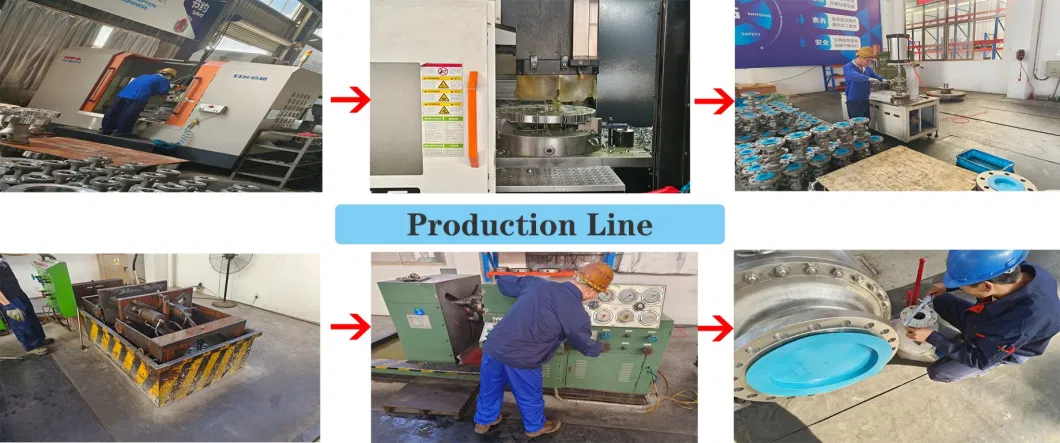

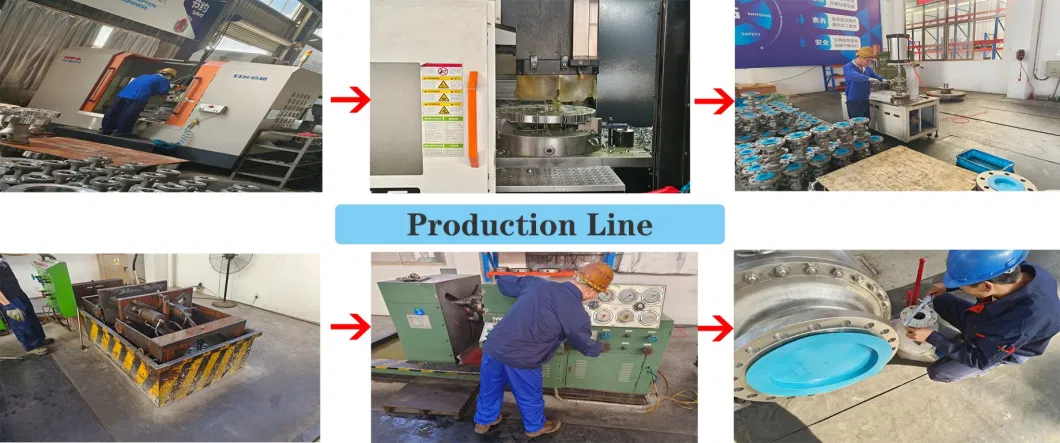

Production process

Certificates & Test reports

Packing&Shipping

FAQ

Q:Are you a trading company or a manufacturer?

We are a manufacturer with a 13,000 square metre factory.

Q:Can you provide assembly drawings?

Yes, we will provide the relevant drawings as soon as possible if you need them.

Q:How do you guarantee the quality of your products?

A: Before the products leave the factory, our quality inspectors will inspect each product before shipment to ensure the pass rate.

Q: Can you produce different standard valves according to customers' requirements?

A: Yes, please provide specific details, such as model, size, pressure, material and so on.

Q:How long is your delivery time?

A: Usually 15-30 days, it depends on the order quantity and our storage.

Diaphragm valves (or membrane valves) consists of a valve body with two or more ports, a diaphragm, and a "weir or saddle" or seat upon which the diaphragm closes the valve. The valve is constructed from either plastic or metal.

Originally, the diaphragm valve was developed for use in industrial applications. Later on the design was adapted for use in the bio-pharmaceutical industry by using compliant materials that can withstand sanitizing and sterilizing methods.

There are two main categories of diaphragm valves: one type seals over a "weir" (saddle) and the other (sometimes called a "full bore or straight-way" valve) seals over a seat. The weir or saddle type is the most common in process applications and the seat-type is more commonly used in slurry applications to reduce blocking issues but exists also as a process valve. While diaphragm valves usually come in two-port forms (2/2-way diaphragm valve), they can also come with three ports (3/2-way diaphragm valves also called T-valves) and more (so called block-valves). When more than three ports are included, they generally require more than one diaphragm seat; however, special dual actuators can handle more ports with one membrane.

Diaphragm valves can be manual or automated. Their application is generally as shut-off valves in process systems within the industrial, food and beverage,pharmaceutical and biotech industries. The older generation of these valves is not suited for regulating and controlling process flows, however newer developments in this area have successfully tackled this problem.

In addition to the well known, two way shut off diaphragm valve, other types include: Three way zero deadleg valve, sterile access port, block and bleed, valbow and tank bottom valve.

Media | water, oil, steam, liquid etc. |

| Medium Temperature | -10°C~180°C |

| Pressure | 0.2~2.5Mpa |

| Material | stainless steel |

| Port size | 1/2″~ 8″ |

| Orifice | DN15-200 |

| AT actuator | single action/dual action |

| Seal | PTFE |

| Voltage tolerance (AC) | ±10% |

| Voltage tolerance (DC) | ±1% |

Production process

Certificates & Test reports

Packing&Shipping

FAQ

Q:Are you a trading company or a manufacturer?

We are a manufacturer with a 13,000 square metre factory.

Q:Can you provide assembly drawings?

Yes, we will provide the relevant drawings as soon as possible if you need them.

Q:How do you guarantee the quality of your products?

A: Before the products leave the factory, our quality inspectors will inspect each product before shipment to ensure the pass rate.

Q: Can you produce different standard valves according to customers' requirements?

A: Yes, please provide specific details, such as model, size, pressure, material and so on.

Q:How long is your delivery time?

A: Usually 15-30 days, it depends on the order quantity and our storage.