- Overview

- Product Description

- About Product

- Unique FAQs

Basic Info.

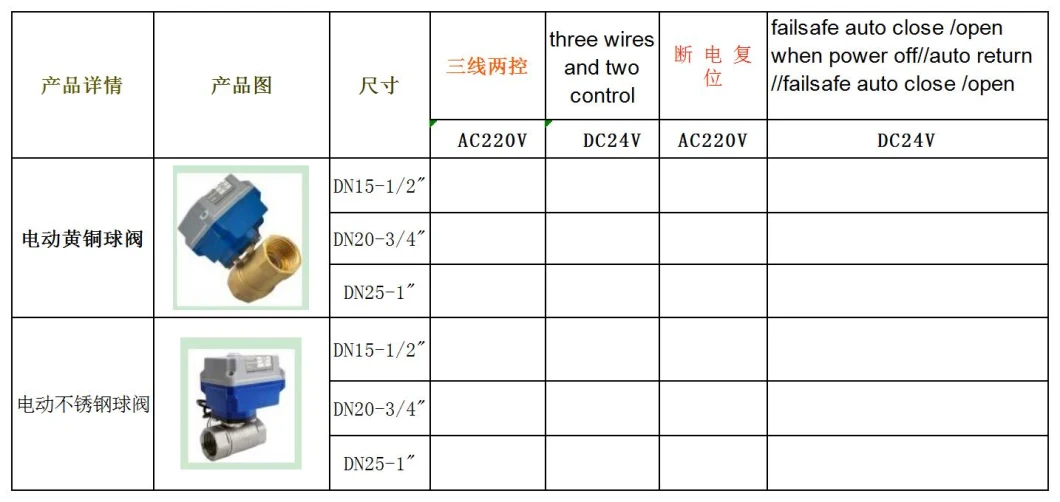

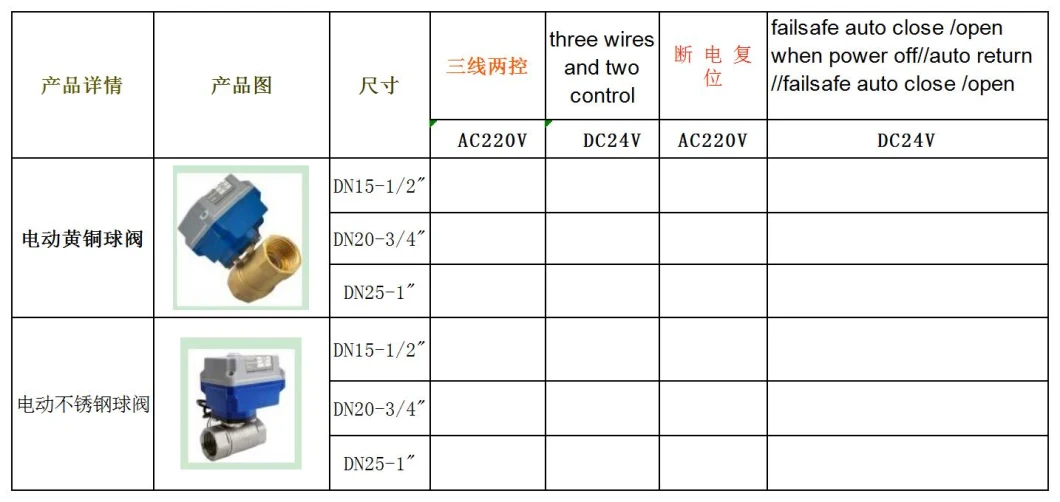

Model NO.

failsafe auto close /open when power off

Driving Mode

Electric

Nominal Pressure

PN1.0-32.0MPa

Channel

Straight Through Type

Structure

Oil Seal Ball Valve

Type

Flexible Ball Valve

Function

Control Flow Valve

Temperature

Normal Temperature

Application

Industrial Usage, Water Industrial Usage, Household Usage

Ambient Temperature

15-50 Celsius

Working Temperature

0-90 Celsius

Working Pressure

10 Bar Max.

Open/Close Time

5 Sec.

Rated Protection

IP67

Nominal Voltage

AC230V Working Current 0.5 AMPS

Specifications

Compact Design Light Weight Small Actuator with Fa

Size

DN15-1/2"

Pressure

Medium Pressure

Transport Package

Bubble Wrap Plus Carton

Specification

DC12V 24V AC110 220V 380V

Trademark

LEADWIN

Origin

China

Production Capacity

3000piece/Day

Packaging & Delivery

Package Size

10.00cm * 10.00cm * 16.00cm

Package Gross Weight

1.200kg

Lead Time

15 days (1 - 1000 Pieces)

To be negotiated ( > 1000 Pieces)

To be negotiated ( > 1000 Pieces)

Product Description

Mini Electric Ball Valve

Compact design and light weight, small electrical actuator with fail-safe function (NC)

Advantage:electric motorized stainless ball valve are popular and widely preferred by many people and industries for several reasons:

2.Hygiene and Cleanliness: Stainless steel is a hygienic material that is easy to clean and sterilize. This makes stainless steel ball valves ideal for applications in the food and beverage industry, pharmaceuticals, and other industries where hygiene and cleanliness are crucial.

3.Wide Temperature Range: Stainless steel can operate effectively in a broad temperature range, from extreme cold to high heat, making it suitable for diverse applications across different industries.

2.What role do valve electric actuators play in preventing leaks and spills in industrial processes?

Valve electric actuators, with their precise control capabilities, play a crucial role in preventing leaks and spills. By swiftly and accurately modulating valve positions, these actuators contribute to the overall safety and integrity of industrial processes, reducing the risk of environmental incidents.

3.Are there advancements in remote monitoring and control of valve electric actuators?

Yes, advancements in communication technologies have facilitated remote monitoring and control of valve electric actuators. Smart actuators, equipped with connectivity features, allow operators to monitor and adjust valve positions remotely, enhancing operational flexibility and efficiency.

4.How do valve electric actuators contribute to process optimization in manufacturing plants?

Valve electric actuators contribute to process optimization by providing precise control over fluid flow. This level of control enhances the overall efficiency of manufacturing processes, ensuring consistent quality and minimizing wastage.

5.What measures are in place to ensure the cybersecurity of smart valve electric actuators?

As smart technologies become more prevalent, ensuring the cybersecurity of valve electric actuators is paramount. Manufacturers implement robust security measures, including encryption and authentication protocols, to safeguard against cyber threats and unauthorized access.

Compact design and light weight, small electrical actuator with fail-safe function (NC)

PRODUCT DESCRIPTION | ||

| TECHNICAL PARAMETERS | ||

| Description | ABS/pc+PBT | |

| Electric actuator | Nylon | |

| Screw | SS304 | |

| O-ring | Epdm/Fpm | |

| Stem | pvdf+SS304/SS316/Brass | |

| Valve Body | UPVC /CPVC/SS304/Brass | |

| O-ring | Epdm/FPM | |

| Valve Seat | PTFE | |

| Ball | UPVC /CPVC/SS304/Brass | |

| WIRING DIAGRAM | |||||

| Wiring Diagram JV01 Voltage:Dc3-6v/12v/9-24v | |||||

| 1.Connecting SW to OPEN,the valve opens,getting the position,automatically power off, the vaiveremain fully open position | |||||

| 2.Connection SW to CLOSE,the valve close,getting the position,automatically power off,the valve remains side passes position(fully closed) | |||||

| Wiring Diagram JV02 Voltage:DC3-6V/12V19-24V | |||||

| 1.Connecting SW to OPEN,the valve opens.getting the position,automatically power off, the vaiveremain fully open position | |||||

| 2.Connection SW to CLOSED,the valve close,getting the position,automatically power off,the valve remains side passes position(fully closed) Note:AC24VIAC220V can only be usedfor JEVE-50K series electric valves | |||||

| Wiring Diagram JV03 Voltage:DC3-6V/12V IADC9-24V IAC220V | |||||

| 1.Connecting SW,the valve opens,getting the position,automatically power off,the valve remain fully open position | |||||

| 2.DisConnectingSW,the valve close,getting the position,automatically power off,the valve remains side passes position(fully closed) Note:When power is DC voltage and Red Wires is "+",Blue is "-" | |||||

| Wiring Diagram JV04 Voltage:DC3-6VIADC9-24VIAC220V | ||||||||

| 1.SW connecting,the valve open,getting the position and the power off automatically,the valve remains fully open/close position | ||||||||

| 2.SW disconnecting,the valve close,getting the position and power off automatically,the valveremains fully open/close position | ||||||||

Common failures and processing methods

Fault cause:- Power not connected

- Voltage below level or incorrect

- Terminal loose or poor contact

- Over temperature protection of motor

- Connect power

- Check whether voltage is within the normal range

- Check and correctly connect terminal

- Check whether valve gets stuck or torque value is too big

Advantage:electric motorized stainless ball valve are popular and widely preferred by many people and industries for several reasons:

- Corrosion Resistance: Stainless steel is highly resistant to corrosion and rust, which makes it suitable for use in a wide range of environments, including those with exposure to moisture, chemicals, and corrosive substances. This corrosion resistance ensures the longevity of the valve and reduces maintenance costs.Durability: Stainless steel is known for its durability and ability to withstand harsh conditions. Stainless steel ball valves are robust and can endure high-pressure, high-temperature, and abrasive applications, ensuring a longer service life.

2.Hygiene and Cleanliness: Stainless steel is a hygienic material that is easy to clean and sterilize. This makes stainless steel ball valves ideal for applications in the food and beverage industry, pharmaceuticals, and other industries where hygiene and cleanliness are crucial.

3.Wide Temperature Range: Stainless steel can operate effectively in a broad temperature range, from extreme cold to high heat, making it suitable for diverse applications across different industries.

1.Can valve electric actuators be retrofitted to existing systems?

Yes, in many cases, valve electric actuators are designed to be retrofit-friendly. However, it's crucial to consider compatibility, sizing, and potential modifications to ensure a seamless integration into existing systems. Consulting with manufacturers and industry experts can provide guidance on retrofitting options.2.What role do valve electric actuators play in preventing leaks and spills in industrial processes?

Valve electric actuators, with their precise control capabilities, play a crucial role in preventing leaks and spills. By swiftly and accurately modulating valve positions, these actuators contribute to the overall safety and integrity of industrial processes, reducing the risk of environmental incidents.

3.Are there advancements in remote monitoring and control of valve electric actuators?

Yes, advancements in communication technologies have facilitated remote monitoring and control of valve electric actuators. Smart actuators, equipped with connectivity features, allow operators to monitor and adjust valve positions remotely, enhancing operational flexibility and efficiency.

4.How do valve electric actuators contribute to process optimization in manufacturing plants?

Valve electric actuators contribute to process optimization by providing precise control over fluid flow. This level of control enhances the overall efficiency of manufacturing processes, ensuring consistent quality and minimizing wastage.

5.What measures are in place to ensure the cybersecurity of smart valve electric actuators?

As smart technologies become more prevalent, ensuring the cybersecurity of valve electric actuators is paramount. Manufacturers implement robust security measures, including encryption and authentication protocols, to safeguard against cyber threats and unauthorized access.